Why Bolted Tanks are the Best Choice for Your Industrial Storage Needs

When it comes to industrial storage, there are a lot of options to choose from. From concrete silos to welded steel tanks, the choices can be overwhelming. But bolted tanks are the clear winner for those who want the most reliable and cost-effective storage solution. Bolted tanks offer a number of benefits that make them the best choice for industrial storage needs. They are durable, versatile, and easy to install, making them a top choice for businesses of all sizes. In this article, we’ll examine why bolted tanks are the best choice for your industrial storage needs and how they can help you streamline your operations and save money in the long run. So, whether you’re looking to store water, chemicals, or other materials, read on to find out why bolted tanks are the ultimate storage solution.

Types of industrial storage tanks

Industrial storage tanks play a critical role in many industries, from agriculture to manufacturing. They store a wide range of materials, including liquids, gases, and solids. Several industrial storage tanks are available, including concrete silos, welded steel tanks, and bolted tanks. Each type of tank has its own advantages and disadvantages, depending on the business’s specific needs. Concrete silos are a popular choice for storing materials like grain and cement. They are durable and can withstand extreme weather conditions, making them ideal for outdoor storage. However, they are not easily moved and can be expensive to construct. Welded steel tanks are also a common choice for industrial storage. They are strong and can be customized to fit specific needs. However, they are often expensive to build and require skilled labor to install. On the other hand, bolted tanks offer several advantages over other types of industrial storage tanks. They are versatile, easy to install, and cost-effective. Plus, they can be used for a wide range of applications, making them a popular choice for businesses of all sizes.

What are bolted tanks?

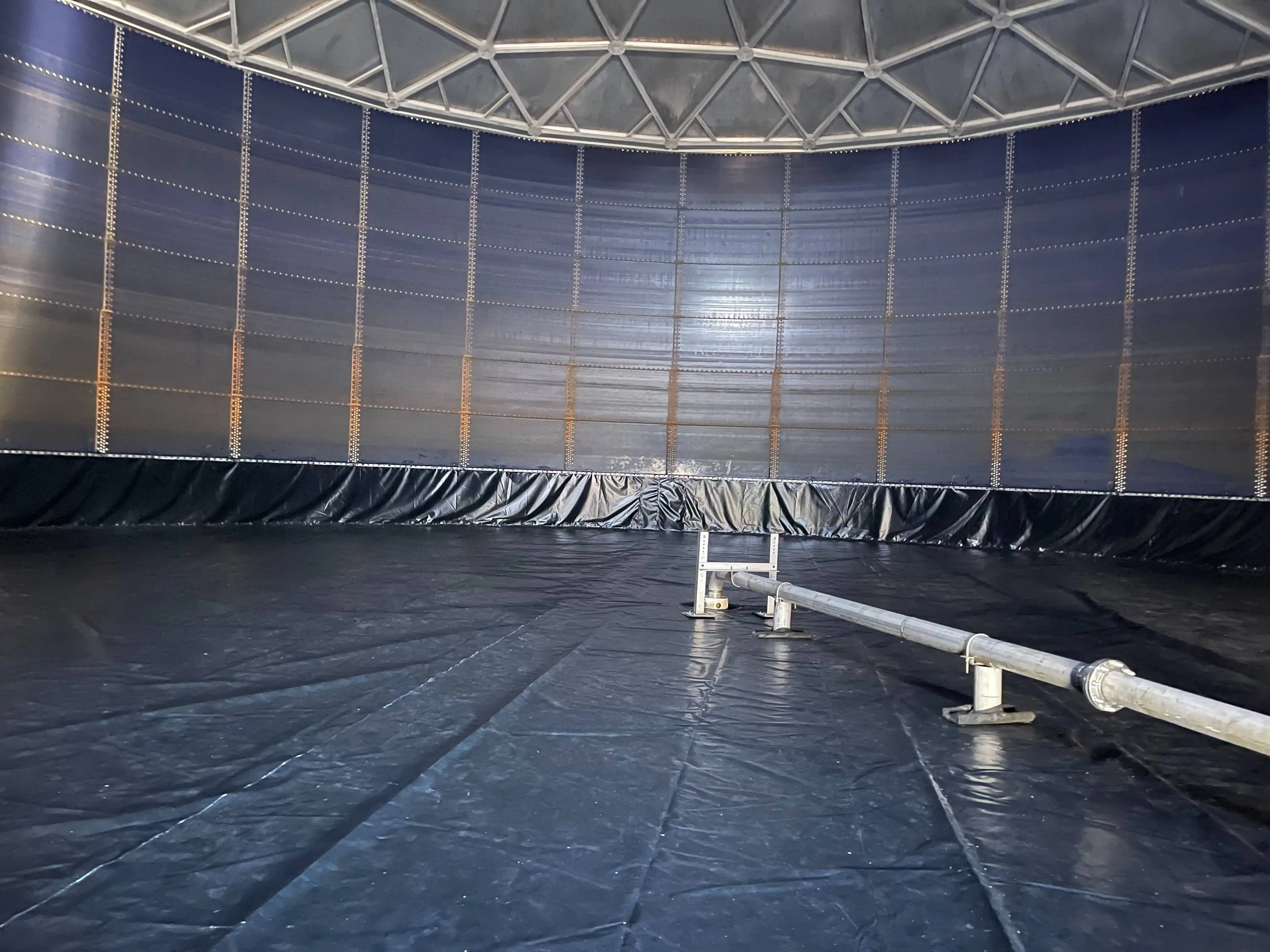

Bolted tanks are modular tanks that are made up of individual steel panels that are bolted together on-site. They are available in a range of sizes and configurations, making them suitable for a wide range of applications. Bolted tanks are typically made from high-quality steel and coated with a protective finish to prevent corrosion and extend lifespan.

One of the most significant advantages of bolted tanks is that they can be easily transported to the installation site, which makes them ideal for remote locations. They are also easy to assemble, which means they can be installed quickly and with minimal disruption to the surrounding area. Plus, bolted tanks can be disassembled and moved to a new location if needed, which makes them a flexible storage solution.

Advantages of bolted tanks

There are several advantages to using bolted tanks for industrial storage. Here are some of the key benefits:

Durability

Bolted tanks are made from high-quality steel designed to withstand harsh weather conditions and resist corrosion. They are also coated with a protective finish that helps to extend their lifespan. This means that bolted tanks are a durable and long-lasting storage solution that can withstand the test of time.

Versatility

Bolted tanks are available in a wide range of sizes and configurations, making them suitable for various applications. They can be used to store liquids, gases, and solids and customized to fit specific needs. This means that bolted tanks are versatile storage solutions that can be tailored to meet the unique needs of your business.

Easy installation

One of the biggest advantages of bolted tanks is that they are easy to install. The individual steel panels are bolted together on-site, which means that there is no need for skilled labor or specialized equipment. This makes the installation process quick and easy, which can save you time and money.

Cost-effective

Bolted tanks are a cost-effective storage solution that can save you money in the long run. They are typically less expensive to construct than other industrial storage tanks, and their modular design means that they can be easily expanded or relocated if needed. Plus, bolted tanks require minimal maintenance, which can further reduce your costs.

Bolted tank applications

Bolted tanks can be used for a wide range of applications in various industries. Here are some of the most common applications:

Water storage

Bolted tanks are a popular choice for storing water, whether it’s for drinking, irrigation, or firefighting. They can be customized to fit specific needs, such as underground or elevated storage, and can be easily expanded if additional capacity is needed.

Chemical storage

Bolted tanks are also commonly used for storing chemicals, such as acids, fertilizers, and pesticides. They are resistant to corrosion and can be coated with a variety of protective finishes to prevent chemical reactions.

Check our liquid bolted tanks for more information.

Grain storage

Bolted tanks can be used for storing grain and other agricultural products. They are a popular choice for farmers and food processors because they are easy to clean and can be customized to fit specific needs.

Check our dry bolted tanks for more information.

Oil and gas storage

Bolted tanks also store oil and gas products, such as crude oil, diesel fuel, and natural gas. They can be customized to fit specific needs, such as underground or aboveground storage, and withstand extreme weather conditions.

Bolted tanks vs. welded tanks

While bolted tanks offer many advantages over other industrial storage tanks, they are not always the best choice for every situation. Here are some of the critical differences between bolted tanks and welded tanks:

Construction

Welded tanks are constructed on-site using specialized equipment and skilled labor. This means that the construction process can be time-consuming and expensive. Bolted tanks, on the other hand, are modular and can be quickly assembled on-site with minimal equipment and labor.

Cost

Welded tanks are typically more expensive to construct than bolted tanks due to the specialized equipment and labor required. However, they may be a better option for more extensive storage requirements, where the cost per unit of storage is lower.

Maintenance

Bolted tanks require minimal maintenance, as they are resistant to corrosion and can withstand harsh weather conditions. Welded tanks, on the other hand, may require more maintenance over time to prevent corrosion and leaks.

Bolted tank construction and installation process

The construction and installation process for bolted tanks is relatively simple. Here are the basic steps:

- Site preparation: The installation site is prepared by leveling the ground and ensuring that it is stable and able to support the weight of the tank.

- Foundation construction: A concrete foundation is poured to provide a stable base for the tank. The foundation is typically larger than the tank itself to provide additional stability.

- Tank assembly: The individual steel panels are bolted together on-site to create the tank. The panels are typically coated with a protective finish to prevent corrosion.

- Roof installation: The roof is installed once the tank is assembled. The roof can be customized to fit specific needs, such as adding vents or access hatches.

- Plumbing and electrical work: The tank is connected to the plumbing and electrical systems, allowing for storing and transferring materials.

Maintenance of bolted tanks

Bolted tanks require minimal maintenance, but taking a few simple steps is important to ensure their longevity and performance. Here are some tips for maintaining bolted tanks:

Regular inspections

Inspect the tank regularly for signs of corrosion or damage. This can help to identify potential issues before they become serious.

Cleaning

Clean the tank regularly to remove any dirt or debris that may accumulate on the surface. This can help to prevent corrosion and extend the lifespan of the tank.

Coating

If the tank is not coated, consider adding a protective coating to prevent corrosion and extend its lifespan.

Cost comparison of bolted tanks vs. welded tanks

When it comes to industrial storage, cost is always an important consideration. While bolted tanks are typically less expensive to construct than welded tanks, the cost per storage unit may vary depending on the business’s specific needs. Here are some factors to consider when comparing the cost of bolted tanks vs welded tanks:

Size

The size of the tank can have a significant impact on the cost. Bolted tanks are available in a range of sizes but may be less cost-effective for very large storage requirements.

Material

The type of material used for the tank can also affect the cost. While both bolted and welded tanks are typically made from steel, the quality and thickness of the steel can vary.

Installation

The installation process for welded tanks may require more specialized equipment and labor, which can increase the cost. Bolted tanks, on the other hand, can be quickly assembled on-site with minimal equipment and labor.

Conclusion: Why bolted tanks are the best choice for your industrial storage needs

Bolted tanks offer a number of advantages over other types of industrial storage tanks. They are durable, versatile, and cost-effective, making them a top choice for businesses of all sizes. Whether you’re looking to store water, chemicals, or other materials, bolted tanks are the ultimate storage solution. With their easy installation and minimal maintenance requirements, bolted tanks can help you streamline your operations and save money in the long run. So, if you’re in need of reliable and cost-effective industrial storage, consider a bolted tank from Weston and Associates for your business, and you won’t be disappointed.

Contact us to discover the #WestonDifference and how we’re changing the future of bolted tanks.