The World's Most Advanced Modular Treatment Plants!

Weston has partnered with Blue Whale Technologies & Energy Water Solutions to produce the world’s most advance modular treatment plants! These treatment plants are a growing need in the storage tank industry including landfill operators, beverage & food processing companies the oil and gas industry and many more!

This partnership allows Weston to provide clients with a complete modular treatment plant that is scalable and will eliminate the overhead, maintenance and operating costs that go with handling wastewater. Weston will design, install and operate our package plants guaranteeing proper treatment of your wastewater. In most cases, our system will lease out for roughly $6 - $8 per barrel (42gallons) treated and evaporated. This includes a dedicated operator and 24/7 Monitoring.

Advantages of BlueFAS BMMR Technology:

- Very Compact – 1⁄4 the size of an activated sludge plant

- Single Pass Technology – No RAS return or WAS wasting

- No F:M Ratio to Monitor or Control

- Effectively Handles Organic Load Fluctuations

- Tolerates Toxic Shocks

- Expandable Biological Treatment Process – just add MBBR media and additional process air as required

- Minimal Operator Attention Required

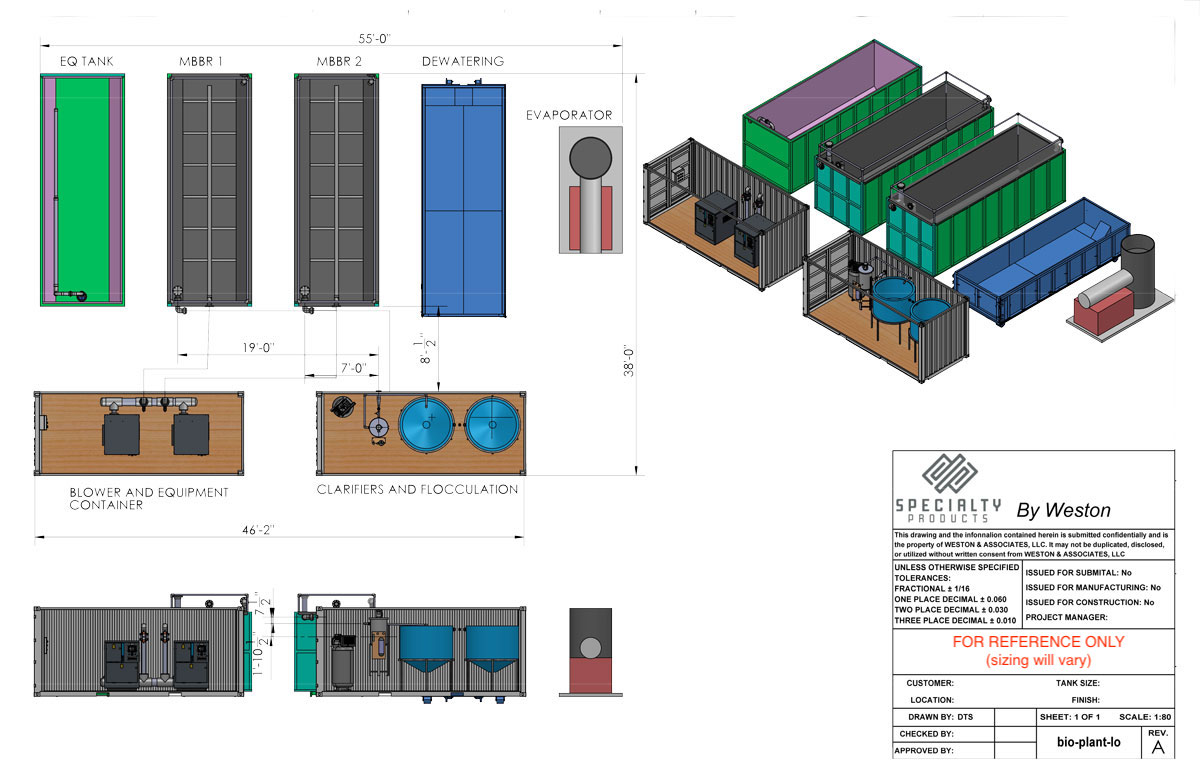

Above is an example of the plant layout to understand the size of the plant.

Operating with our technology most operators are eligible for ESG credits.

ESG Credits Examples:

- Our Plants utilize (if applicable) _the gases landfills produce for beneficial use rather than just flaring it. _(Lower carbon footprint)

- Our system returns clean water to the natural water cycle through treatment & evaporation.

- Removing trucks from the road eliminating the wearing of roadways.

- Removing the need for injection disposal / removing seismicity concerns.

- Closing the loop to return water back to the environment on premises.

- Last but certainly not least, the reduction of disposal / treatment cost with reduced logistic needs.