Weston's NanoCoat and CeramaCoat are an Unbeatable Combo

Reduce Maintenance Costs and Downtime with NanoCoat and CeramaCoat’s Fast Application Time

Bolted storage tanks have become increasingly popular in the industrial and municipal sectors due to their versatility, durability, and ease of installation – these tanks commonly store water, wastewater, chemicals, and other fluids that require safe and reliable containment. However, they require a high-quality coating system that can withstand harsh environmental conditions and prevent corrosion.

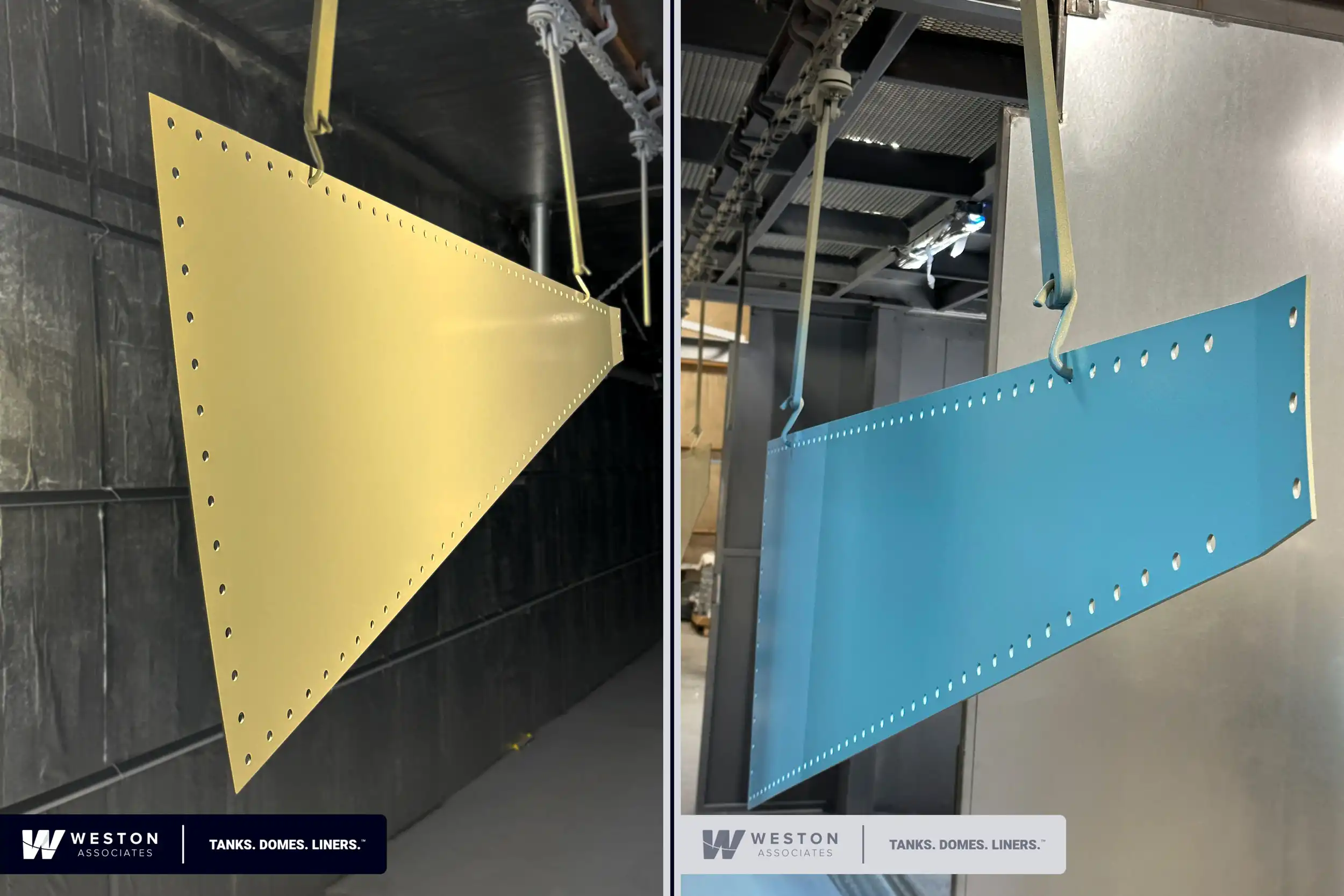

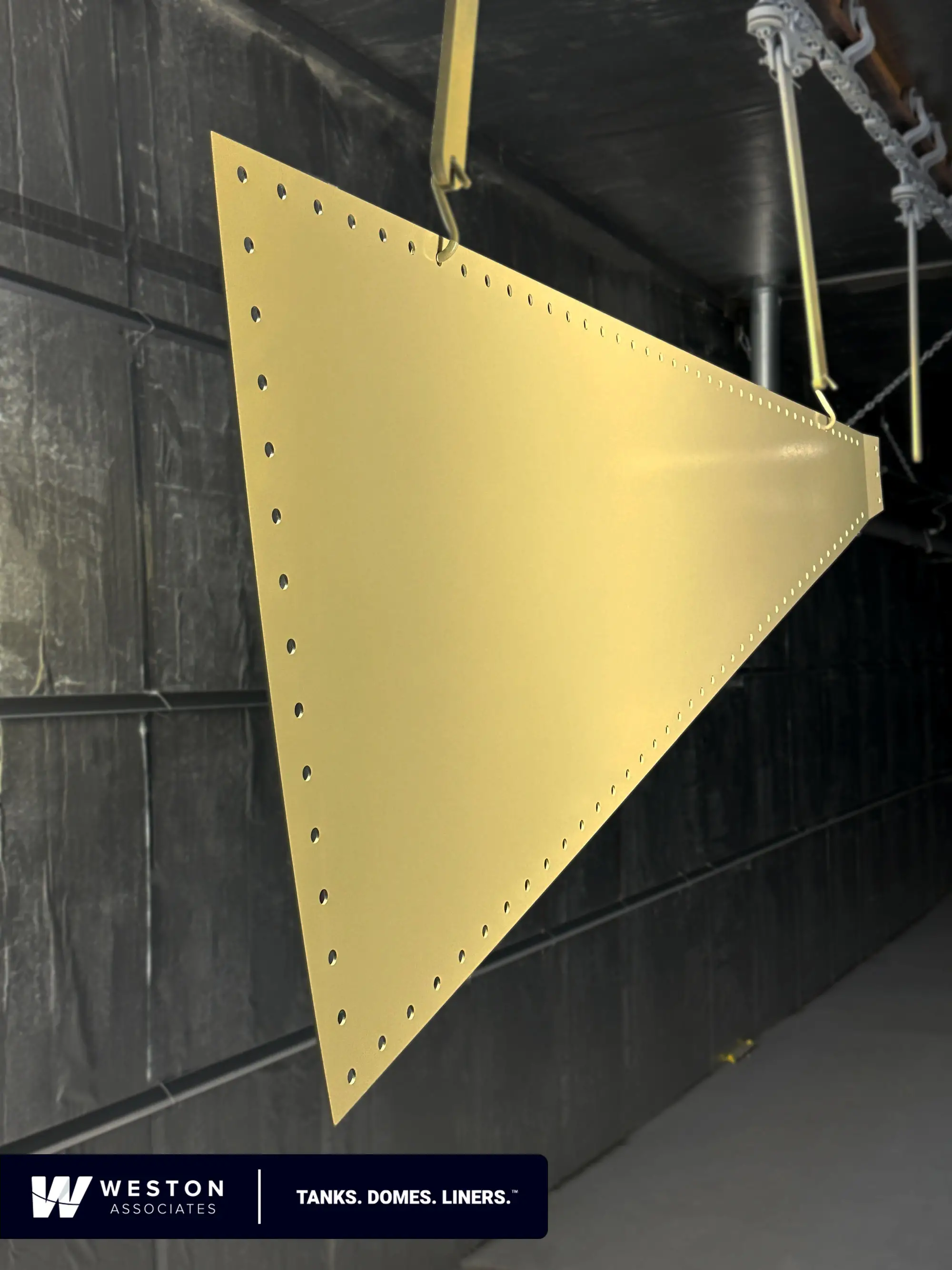

Two products that stand out in the coating industry are Weston NanoCoat (WNC) and CeramaCoat (WCC). Weston has developed these innovative products to address the challenges of coating bolted tanks, especially those made of glass-fused-to-steel or epoxy powder-coated substrates.

Weston NanoCoat is a two-coat system featuring a low VOC epoxy primer and topcoat that offers unbeatable corrosion protection, application time, and labor. One of the most impressive features of Weston NanoCoat is its 2 x 1 wet-edge technology, which allows applicators to apply the topcoat to the primer just 30-45 minutes after the primer has been used. This feature reduces the time it takes to coat bolted tanks and can significantly save labor costs.

On the other hand, Weston CeramaCoat is a thin-film primer that boasts a 45-minute time-to-recoat, a one-year maximum recoat window, and low moisture vapor permeability. CeramaCoat is NSF-approved and mitigates undercutting corrosion, making it an ideal choice for applications that require NSF 61 approval. CeramaCoat also eliminates exposure to reactive metals and Isocyanates, making it a safer and more environmentally friendly option for coating bolted tanks.

Combining both coatings, WNC for the exterior and WCC for the interior of bolted tanks results in an unbeatable performance. This combination offers the benefits of both coatings, including significant reductions in maintenance costs, increased efficiency, worker safety, and long-term performance. This combination results in an unbeatable performance that can reduce maintenance costs, increase efficiency, and provide long-term protection to the tank.

If you have any questions about these coating systems or would like to learn more about how they can benefit your next project, please don’t hesitate to contact our sales team at [email protected].